Microalgae: high quality raw material with immense potential.

The electrostatic application is ideal for customers who require a uniform application who desire to achieve a high-quality application result for the protection of their crops. In addition to the correct maintenance and calibration of equipment for the application of crop protection products, the technological characteristics that the market offers are fundamental. Today, the quality of the application is increasingly important for multiple factors:

- New types of crop protection products where the coverage quality of the plants must be very accurate so as to allow the garrison to maximize its results (ex. resistance inductors)

- Increased adhesion of the pesticide on all crop surfaces

- Reduction of losses due to air drift

- Environmental protection, reduction of leaks due to dripping on the soil and dispersion of crop protection products in the area

- The potential for economic savings for the farm and a reduction in the number of operations to be carried out.

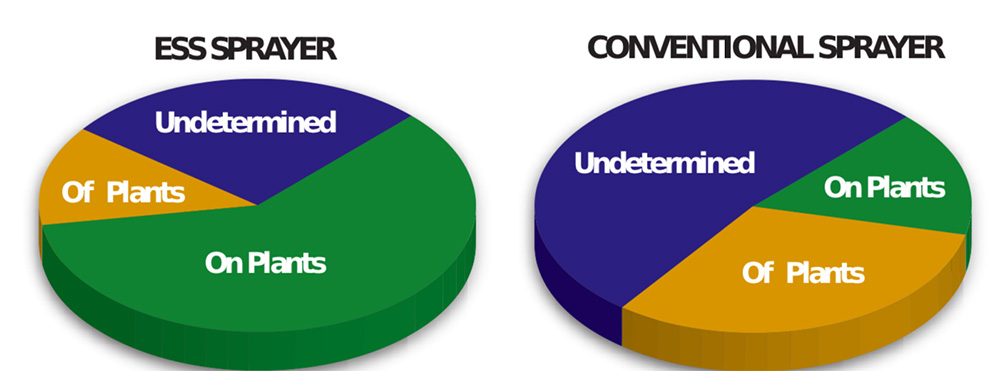

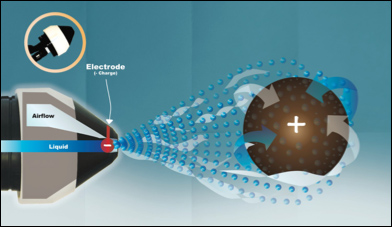

The first to work on this technology was the University of Georgia which invented an electrostatic sprayer that converts more liquid air and electrical current. Air and liquid enter the rear of the nozzle separately. The air moves through the nozzle under pressure and meets the liquid at the tip of the nozzle causing the formation of spray droplets with a diameter of 30 to 60 microns. On the tip of the nozzle there is a small electrode that applies an electric charge to the spray. The electric charge causes a natural force of attraction between the spray droplets and the surface of the target, similar to the attraction between items of clothing created by a tumble dryer. The attraction to the target surfaces refers to, “Coulomb’s Law,” which states that any two charged objects will create a reciprocal force.

The charge on the droplets although small, pulls the spray towards the target at 75 times the force of gravity. Spray droplets can reverse direction moving against gravity to coat all the sides of an object.

This technology exploits the principle of physics to obtain better coverage and reduce the environmental impact by allowing the use of smaller quantities of chemicals. In addition, this electrostatic technology uses air assistance to facilitate spray delivery. Air is needed in electrostatic spraying to create tiny droplets (30-60 microns, 900 times smaller than conventional sprayers) that can travel in the turbulent air flow in dense areas.

Thanks to these characteristics, the mix of air and water is attracted by the leaves of the plants, both the upper and lower part with a coverage equal to 100%.

The results obtained in the field are exceptional with great future prospects.